| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Model No.: 40ZLX-40

Impeller Number: Single-Stage Pump

Working Pressure: Middle Pressure Pump

Influent Type of Impeller: Single Suction Pump

Position of Pump Shaft: Vertical Pump

Pump Casing Combined: Verticaljoint Surface Pump

Mounting Height: Since Irrigation Centrifugal Pumps

Impeller: Semi-Open

Usage: Pumps

Pump Bearing Brands: SKF, NSK Or Reputed Chinese Brands

Pump Materials: CD4MCU, Cr26, Cr30, Zg40mn2 Etc.

Motor Brands: ABB, Siemens Or Reputed Chinese Brands

Additional Info

Packaging: Wooden case or Frame steel Case

Productivity: 1100000 sets/year

Brand: GAOFENG

Transportation: Ocean,Land,Air

Place of Origin: Zigong,Sichuan,China

Supply Ability: 110000 sets/month

Certificate: ISO9001

HS Code: 8413709990

Port: Shanghai,Guangxi,Chengdu

Product Description

1.ZLX type pump is the new type vertical submerged slurry pump designed according to the standard JB/T8096-1998 of our country. This series pump by direct connection and used to deliver the liquid with suspended solids in the medium. The maximum weight concentration of liquid delivered is ≤60% and the medium temperature is ≤80℃. Allowing a small amount of large solid particles in, but its diameter should be smaller than 80% of the minimum flow surface. This pump is widely applied to chemical industry, electric power, oil industry, mining, cement etc.

2.This pump uses double supporting cantilever structure that improves the reliability and stability of pump operation. The installation depth of pump (from pithead to impeller center) is 0.8, 1.0, 1.2 meters. When the total underwater depth (from the installation wellhead to the pump inlet) is less than 1.5 m, the overall structure is adopted.. If the submerged total depth is above 1.5 meter, the pump uses inlet suction pipe structure which guarantees the suction performance and the length of suction pipe should below 2 meters. To make the pump normal operation when it starts and never occurs cavitation, pump has to start at high water level, that requires the liquid level should be 250-300 mm higher than the impeller center when pump starts, and pump can be low water level when it operates. This pump uses the structure with no shaft seal and there is no need to use external flushing water and more water-saving. Flow passage components use wear-resisting alloy casting, so the using life is longer than normal metal.

Submerged Pump With High Quality Parameters:

The Configurations of motor engine pump's Performance:

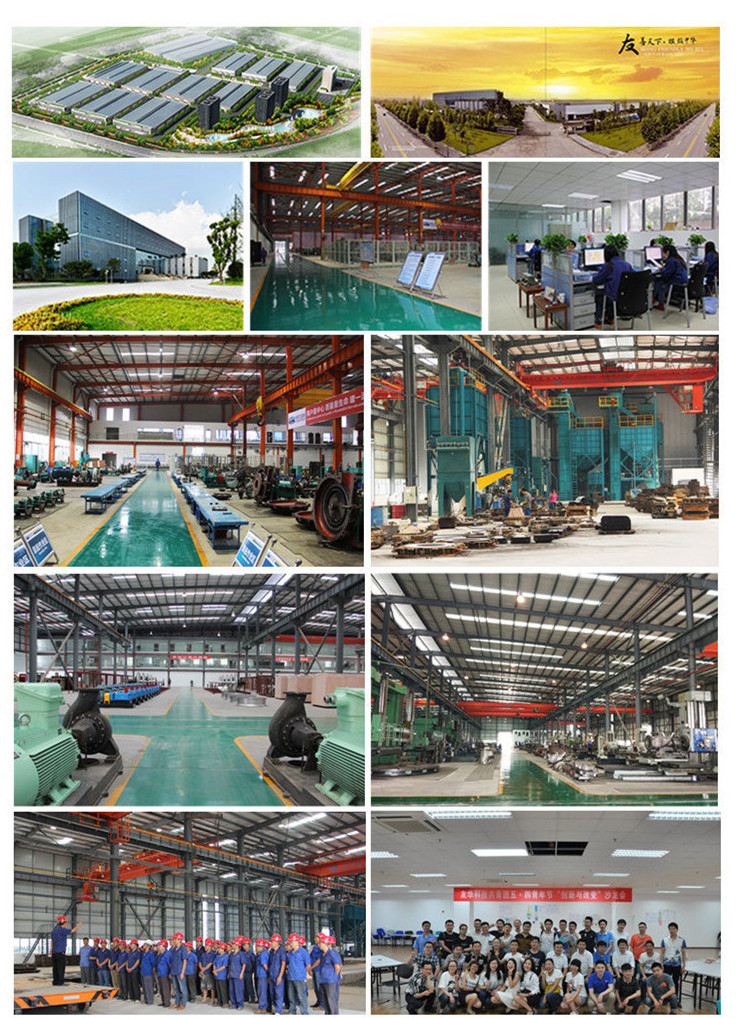

Company View:

Product Categories : Industrial Pumps > Pumps For Coal Industry