| Unit Price: | USD 700.0000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Model No.: 150S50 A

Impeller Number: Single-Stage Pump

Working Pressure: Low Pressure Pump

Position of Pump Shaft: Horizontal Pump

Pump Casing Combined: Horizontal Split Pumps

Mounting Height: Suction Centrifugal

Impeller: Open

Usage: Pump

Influent Type of Impeller: Double-Suction Pump

Medium: Chemical Liquid

Head: 9--140 M

Additional Info

Packaging: Wooden case or Frame steel Case

Productivity: 1100000 sets/year

Brand: GAOFENG

Transportation: Ocean,Land,Air

Place of Origin: Zigong,Sichuan,China

Supply Ability: 110000 sets/month

Certificate: ISO9001

HS Code: 8413709990

Port: Shanghai,Guangxi,Chengdu

Product Description

S type double-suction pump

S type double-suction pump can be named by Double-suction water pump,chemical liquid water pump or multipurpose single stage double suction pump.

Multipurpose Single Stage Double Suction Pump---Brief introduction

S type pump is the horizontal centrifugal pump of single-stage, double-suction and open in the middle. It is used for transporting clean water and other liquids similar to the clear water with physical and chemical characteristics. The liquid temperature should below 80℃. Often call them----water pump for agricultural irrigation.

The head of pump produced by our company is 9-140 meters, the capacity is 126~7590 cubic meter/hour. The pump is applicable to factory, mining, municipal water supply, power station, hydraulic engineering, the irrigation of farm and draining water-logged with a very wide using range.

The meaning of Chemical Liquid Water Pump(e.g 150S50A)

150---the inlet diameter is 150mm

S------single stage double suction pump

50----Head is 50 m

A-----the code of the impeller

Features and charts of Double-suction Water Pump

1. Structure features

The intake suction and outlet suction of S type pump are all below the pump axial lead, perpendicular to the axial lead appears horizontal direction, the capsid horizon and in the open double, the pump cover located by the taper pins with external thread. Detach the pump cover and easy to check, no need to detach the intake and outlet pipe and motor. See form the transmission direction it is clock-wise.

The main spare parts are: pump body, pump cover, impeller, shaft, double-suction sealing-ring, shaft-sleeve, bearing parts and coupling-parts etc, besides the material of shaft is quality carbon steel, the others are all cast iron. Using carbon steel or stainless steel is according the requirements of users.

The pump body and pump cover constitute of the workshop of impeller. There is a pipe thread hole to install vacuum gage and manometer on the water outlet flange. At the bottom of intake and outlet flange there set a pipe thread hole for drainage.

At the top of pump cover there set a pipe thread hole to gas leakage.

After the check of static balance of impeller, fix it on the pump shaft by the key, shaft sleeve and sleeve nut at the two sides, the direction of axial force adjusts by the sleeve nut. Make the shape of impeller be symmetry, the liquid gets into the impeller from two sides to balance the axial force, if there remains axial force supported by the single-row radial ball bearing at the end of shaft.

The two side of pump supported by the pump shaft, installed coupling-shaft at the right and directly connect to the motor. (If necessary to deliver by the belt, so need to set a stand.)

The bearing is set in bearing body and installed at the two sides of pump body. Use the butter to lubricate the single-row radial ball bearing.

The double-suction seal-ring is used to reduce leakage of liquid water back into the suction chamber. For wearing parts, spare parts should be replaced after wearing.

Shaft sleeve is for fixing wheel shaft position and protecting shaft and it is wearing component, so spare parts should be replaced after wearing.

Using soft packing seal is to prevent air penetration into the pump and the large amount of liquid leakage. Fitted between the packing rings in the packing, packing compression level must be appropriate. Work a small amount of high-pressure water pump through the pump cover in the open surface of the trapezoidal groove into the packing chamber, which is for water seal.

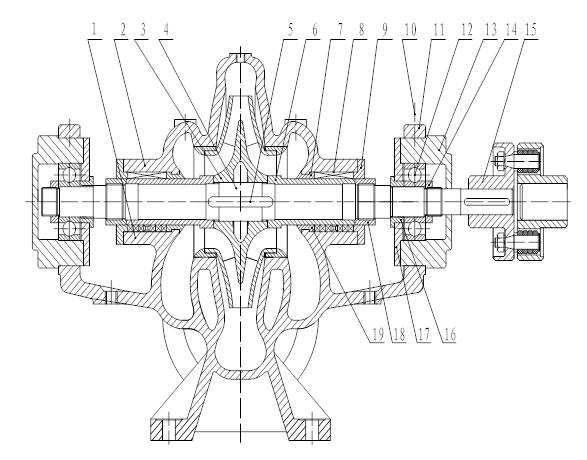

2.Structure figures

1.casing 2. pump covering 3.impeller 4.shaft 5.key 6.shaft sleeve 7.packing sleeve 8.seal 9.gland 10.single-row radil ball bearing 11.bearing 12.locating screw 13.bearing gland 14.round nut 15.coulping 16.bearing gear sleeve 17.bearing end covering 18.bearing nut 19.sealing ring

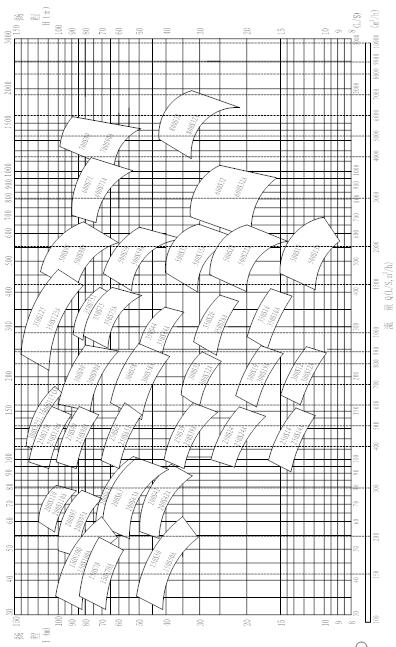

The pump type table

Packing and shippment