| Unit Price: | USD 700.0000 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Model No.: IS 80-65-160

Impeller Number: Single-Stage Pump

Working Pressure: Low Pressure Pump

Influent Type of Impeller: Single Suction Pump

Position of Pump Shaft: Horizontal Pump

Pump Casing Combined: Horizontal Split Pumps

Mounting Height: Suction Centrifugal

Impeller: Open

Usage: Pump

Clear Water Pump: Single Suction

Additional Info

Packaging: Wooden case or Frame steel Case

Productivity: 1100000 sets/year

Brand: GAOFENG

Transportation: Ocean,Land,Air

Place of Origin: Zigong,Sichuan,China

Supply Ability: 110000 sets/month

Certificate: ISO9001

HS Code: 8413709990

Port: Shanghai,Guangxi,Chengdu

Product Description

IS type single-stage and single-suction centrifugal pump

IS type single-stage and single-suction centrifugal pump can be named by clear water pump,single stage water pump or single suction centrifugal pump.

Brief introduction

IS type pump is a single-stage single-suction (axial suction) centrifugal pump. This pump is applicable to industrial and city water supply, drainage, and also for the agriculture irrigation and drainage. Used for transporting clean water or other liquids similar to the clear water with physical and chemical characteristics. The temperature should below 80℃.

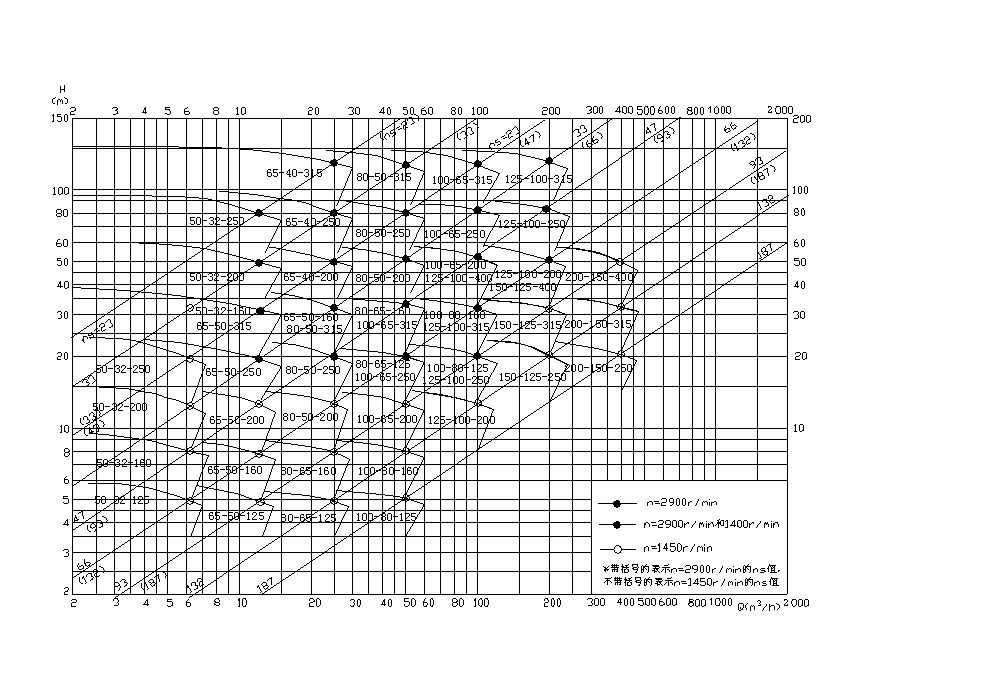

IS type pump series performance range(accounted by the design point)

Revolution:1450r/min~2900r/min

Inlet diameters:50~200mm

Capacity:3.3~460m3/h

Head:4~133m

Features and charts of the pump structure

1.Strcture features

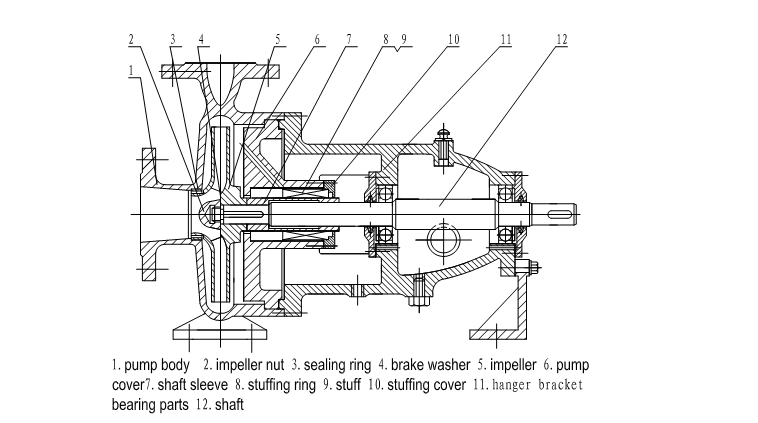

IS series pump design is according to the performance and size stipulated by the international standard ISO2858, mainly made up of pump body, pump cover, impeller, shaft, sealing-ring, shaft sleeve and suspension bearing parts etc (refer to the structure figure).

The part of IS pump body and pump cover, is subdivided at the back of impeller, which is usually said as back door open type. Its advantage is convenient to maintain and no need to move the pump body, intake pipe, outtake pipe, and mend it by withdrawing the rotating parts.

The capsid of pump (pump body and pump cover) constitutes the workshop of pump. Impeller, shaft and rolling bearing build up of the rotating part of pump. The hanger bracket parts support the rotating parts of pump, the rolling bearing support the radial force and axial direction force of pump.

To balance the shaft force of pump, many pump set sealing-ring at the back and front of pump impeller, set balance hole at the back cover plate of impeller. Because the axial direction force of some pumps are not so heavy, there are no sealing-ring and balance hole at the back of impeller.

The axial direction force of pump is made up of stuffing gland, stuffing-ring and stuff etc so as to avoid gas or large amount of water leakage. If there are balance hole at the pump impeller, the empty cavity that full of soft stuff have a connection with the impeller intake, if the liquid at the intake of impeller remains vacuum, the air will be easy to access along the surface of shaft sleeve, so set a stuffing-ring to guide the pressure water in the pump house into the stuffing-ring to seal through the small hole on the pump cover. If there is no balance hole at the impeller, because of the pressure of water at the back of impeller higher than the atmospheric pressure, so the air leakage isn`t exit, so no need to set stuffing-ring.

o avoid the abrasion of shaft, there is a shaft sleeve to protect the stuffing house parts, set the sealing ring of O type between the shaft sleeve and shaft to avoid the air intake or water leakage.

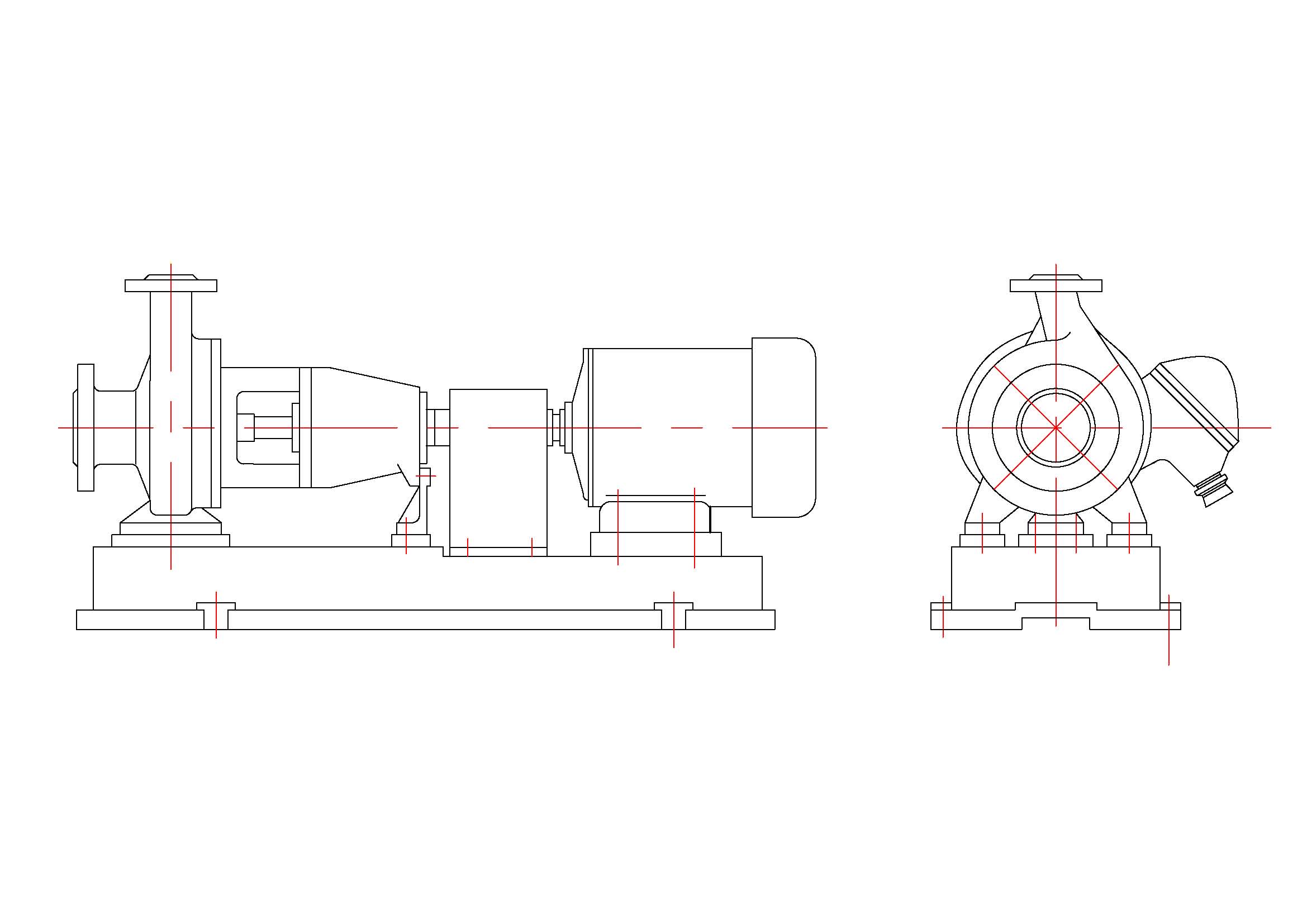

The transmission style of pump is by connecting the flexible shaft-coupling with the motor. The rotating direction is clockwise form the drive end.

2.Structure figures

The pump type table and main performance parameters.

1.Table drawing

2.Outside drawing

Packing and shippment